Production Capability

KINSUN offers a complete production line, consistent quality control and sufficient production capacity. Our production line process capabilities include stamping, molding, injection, assembly and testing capabilities.

Stamping Machine

There are 23 machines in the stamping department. The maximum tonnage of the machines is 80 tons, and the minimum tonnage is 3 tons. Among them, 3 are high-speed presses, and 2 are Swiss BRUDERER automatic high-speed presses of 20 tons and 50 tons, respectively. Switzerland is a country that places great emphasis on precision, and BRUDERER's punching machine is no exception. The accuracy of the products produced by it is also very high. The machine table is also equipped with a punching force device. When there is a chipping inside the mold, it will immediately stop the protection of the mold, and also avoid the possibility of poor product flow out.

And the speed of the machine can reach up to 2,000 in one minute. When the order volume of the customer is large, it is sufficient to cope with it.

The other is Japan's YAMADA (40 tons) automatic high-speed press. The machine is also equipped with a die blind spot detector. This detector is much more sensitive than Taiwan. And this station is a knuckle-joint presses punch. The knuckle-joint presses punch has the characteristics of a short stop when the slider moves to the bottom, that is, bottom dead point. For some folded products, its stability is high.

We also have 50 tons, 60 tons, and 80 tons machines to produce a wide range of iron shells.

Material

The materials we can produce include phosphor bronze, red copper, brass, iron, white iron, battery soft iron, zinc-tin-nickel alloy and beryllium copper. The thinnest is 0.10mm, and the thickest is 2.0mm.

Molding

In order to ensure the competitive advantage of the precision parts industry, we have successively introduced precision mold parts processing machines from Europe, the United States, and Japan. We have precision machining centers, CNC turning and milling machines, wire cutting machines, optical projection grinding machines, CNC electric discharge machines, and various other measuring machines. The monthly production capacity of precision molds and fixtures is up to 50 sets, and the processing level of mold parts is up to u”. Our extraordinary mold processing and manufacturing technology has greatly reduced our product development cycle, while providing strong production capacity and technical support for the large-scale production of parts and components.

Injection Introduction

1. There are two main types of injection molding machines: horizontal plastic injection molding and vertical plastic injection molding.

2. Our horizontal machine are all SUMITOMO and FANUC all-electric injection machines (control by the servo is more accurate).

3. We have 7 sets of vertical injection molding machines, 6 of which are hydraulic and 1 is all-electric injection molding machines. The vertical all-electric injection machine is also equipped with servo feeding system and CCD measurement inspection to achieve automatic production and inspection.

4. The quality of injection is based on two major systems of KINSUN QCS and product engineering drawings for inspection, dimensional measurement specifications and appearance criteria, and the number of inspection times.

5. Halogen-free and replacement of different materials all have SOP cleaning methods, and each year will require external testing company to test the halogen value.

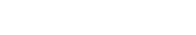

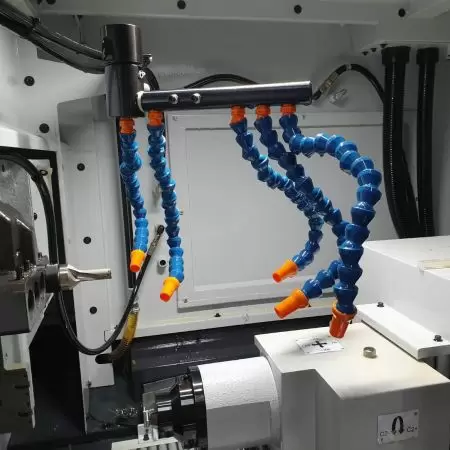

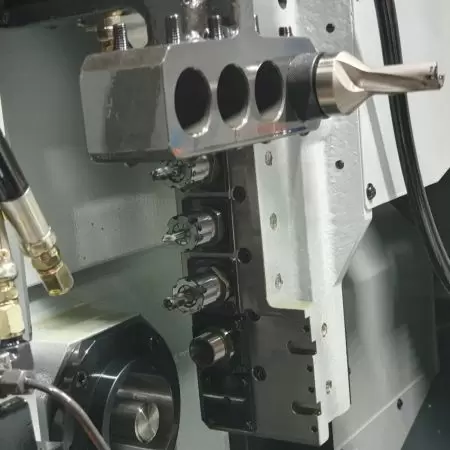

CNC Turning Machine

Kinsun's latest CNC machine. With leading technology and high quality components. GOODWAY SW series Swiss Turning Center provides up to 9-axis control and 4-axis coordinate motion which is highly performanced by using high-speed built-in spindle, complete tooling system and flexible design of hybrid guide bush. It can CNC For Stainless SUS316 easily. The SW series offers turning, milling, drilling, tapping and other complicated work requirements for micro and precise parts.

Assembly: Automatic equipment assembly capabilities

After receiving "order confirmation" from the sales department, the production management department translates it into a "production order" and establishes a process control schedule. After the production line is based on the demand of the order and the capacity of the equipment is evaluated, if the production capacity is insufficient, the strain will be caused by overtime or additional equipment. Our automatic machine equipment has CCD vision detection or electrical measurement function can do 100% detection of products.

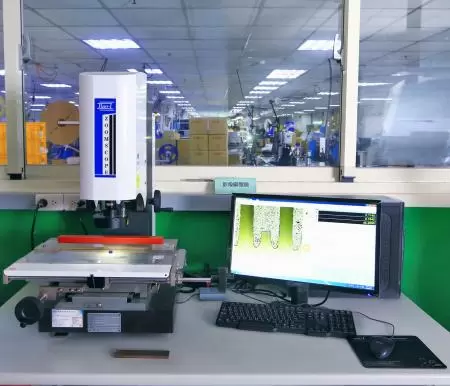

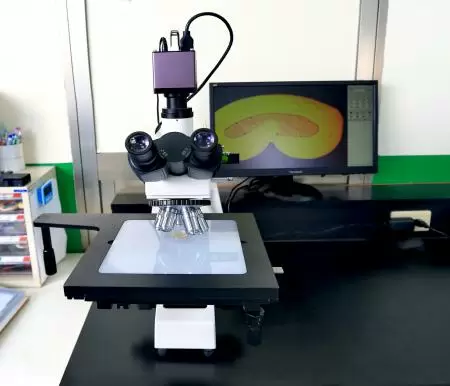

Testing

The Quality Assurance Department has the capability, size, and functionality to inspect KINSUN's manufacturing products to ensure that it meets the product's characteristics to meet customer needs. Our reliability test can meet the research and development engineers' ability to design and develop new products.